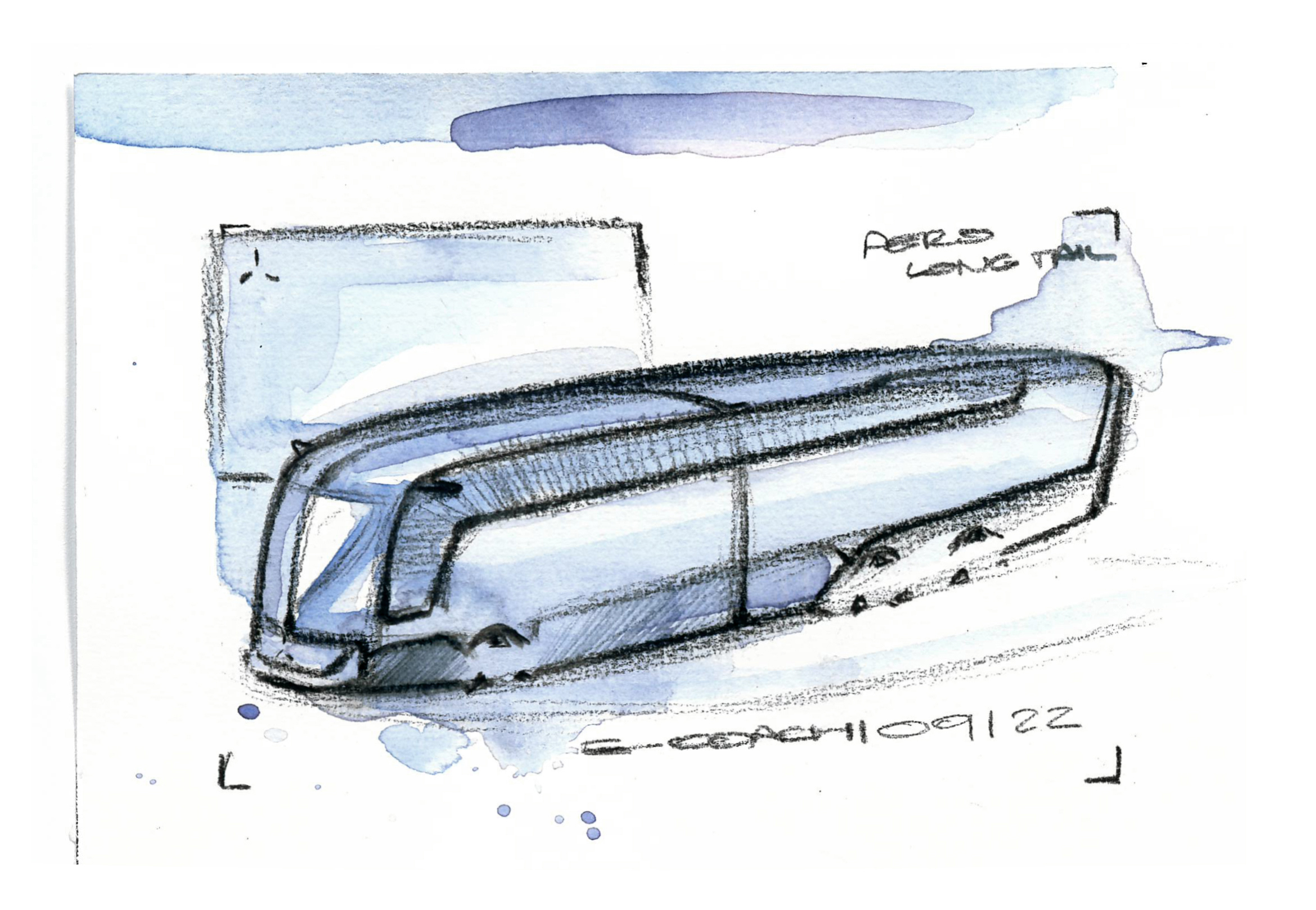

Design-Draft Electrified Coach (ELCH). Foto: Daimler Ruck AG

Design-Draft Electrified Coach (ELCH). Foto: Daimler Ruck AG

The ambitious target has been defined, but the path to get there is currently still open: From the end of this decade, Daimler Buses wants to offer fully electrically powered coaches with its Mercedes-Benz and Setra brands. To accelerate development, Daimler Buses has joined forces with renowned research institutes and practitioners from the industry to form the Electrified Coach project – ELCH for short. The project is funded by the German Federal Ministry of Economics and Climate Protection.

ELCH project: the path to a modular e-drive system for coaches

City buses with fully electric drives, such as the Mercedes-Benz eCitaro, are now a familiar sight on the streets of many German and European cities. Electrically powered coaches are a different story. Their development is much more difficult, as there are numerous high hurdles to overcome before they can be used in practice. Indispensable and sometimes contradictory are the requirements for long range in long-distance transport, flexibility in operation, intermediate charging for batteries, high payload and the space requirements for passengers and luggage. To date, no bus manufacturer has succeeded in developing a battery-electric coach that covers practical ranges and availability for a wide range of operating conditions.

The aim of the Electrified Coach project is to develop a modular powertrain including two emission-free and practical demonstration vehicles over the next four years. They will subsequently be tested under real operating conditions.

Sustainable approach:From energy consumption to manufacturing

In the ELCH project, the partners are taking a sustainable approach. First of all, a modular drive system is being investigated in a concept phase in a model test with a view to energy consumption, range, driving performance, and battery service life. Synergies with components from Daimler Truck’s truck division will be taken into account. In a second step, factors such as overall costs, environmental impact, and possible integration into existing operating concepts of bus companies are incorporated into the results. Based on the concept evaluation, two prototype powertrains are then developed and integrated into demonstrator vehicles. This will allow testing under real operating conditions.

The findings from the construction of the demonstrator vehicles form the basis for planning cost-effective production and assembly processes for electrically powered coaches. In combination with the modular product approach, this enables a rapid production ramp-up.

Target: Practical and economical all-electric touring buses

The acceptance of the technology depends to a large extent on its suitability in practice. This will be systematically recorded for the first time in the project and will serve as a reference for the design of the powertrains. The design space of the vehicles should correspond as far as possible to today’s diesel buses. In addition to their range, the preservation of passenger capacity including the payload for luggage are important prerequisites for the success of e-coaches. In addition to the powertrain and battery technology, the project partners attach significant importance to the topics of aerodynamics and lightweight construction.

In addition, the cost-effectiveness of the resulting vehicle concepts will be evaluated from the operator’s point of view and taken into account in the concept definition. The aim is to identify cost-effective concepts for individual vehicles and entire fleets of electrically powered coaches for the various application profiles. Test drives on real customer cycles also form the basis for further development of the powertrains towards series production readiness.

Project partners: researchers and practitioners work hand in hand

The coordinator of the publicly funded project is Daimler Buses. Project partners are the Karlsruhe Institute of Technology KIT (ITIV – Institute for Information Processing Technology); the University of Mannheim (MISES – Mannheim Institute for Sustainable Energy Studies); the Technical University of Kaiserslautern (iMAD – Institute for Mechanical and Automotive Design as well as SAM – Chair of Fluid Mechanics and Fluid Machinery) and the operator Flix SE with its green Flix long-distance buses.

Read on in the current eMove360° magazine (German). Download PDF for free or order print version at sabine.metzger@emove360.com